Evolution Of ABS.

Antilock braking technology has been around for nearly a century. Aircraft have had antiskid braking systems since World War II. The earliest antilock braking systems on automobiles date back to the 1920s. Antiskid or antilock braking first became more commonplace on cars and trucks in the 1990s as a positive step toward improved safety and vehicle control during hard braking and slippery conditions.

Although ABS seems complicated, it is actually quite simple in function. If you encounter a skid while braking, the ABS control module senses a slowdown or pause in wheel rotation and modulates brake application to where you can steer out of trouble. In a conventional skid, steering control is lost and the vehicle continues to travel in the direction of lost control. Antilock braking pulses the brakes to where there is a measure of control out of the skid because you have some level of tire traction.

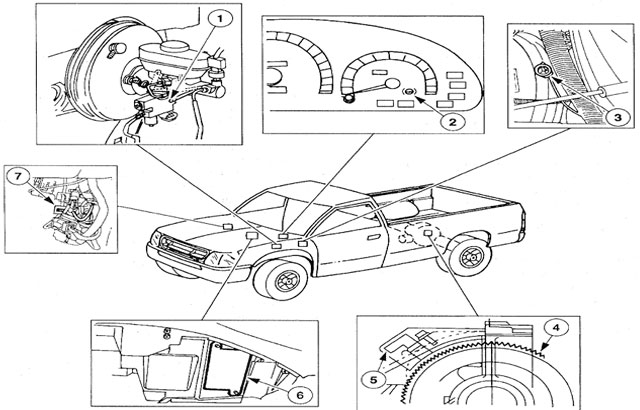

A typical antilock braking system consists of four wheel sensors (sometimes two or three), an antilock electronic control module, and hydraulic control unit, which allows master cylinder hydraulic pressure to all four brakes under normal conditions, and pulsing pressure to each brake when a skid is detected.

ABS Function.

Early antilock braking systems were hydromechanical meaning non-electrical. They were mechanically controlled to modulate brake application. Contemporary antilock braking systems are electrohydromechanical meaning they are computer-controlled brake hydraulic systems.

A vehicle's antilock braking system control module is designed to notify the driver if there is a malfunction in the system with a warning light. Rarely is a malfunction the module or antilock unit itself. Most of the time, it is one or more sensors or wiring to the sensors. Antilock brake sensors are typically magnetic trigger. As the reluctor's teeth pass the sensor, the normal pulsing rhythm of wheel motion indicates normal operation.

It is when the reluctor speed across the sensor changes dramatically (wheel slowdown or stopped) antilock will pulse brake application. When the antilock brake system pulses, it is allowing hydraulic pressure to the brakes to come in rapid fire succession, sometimes as rapidly as 15 times in a second depending on the system, to where there is intermittent braking and some level of steering and braking control.

The antilock braking system electronic module or controller can be integral with the hydromechanical braking controller or it can be separate. There can also be electrical relays that fire when the system is called to duty.

Most antilock braking system malfunctions happen when sensors become contaminated with debris or metal shavings. Malfunctions also occur when sensor wiring becomes damaged resulting in intermittent or no continuity. In more corrosive environments or serious brake system neglect, brake fluid can become contaminated and the hydraulic controlled fails to function.

ABS Types.

There are three basic types of antilock braking systems — four-channel/four sensor, three-channel/three sensor, and one-channel/one sensor. Of course the best scenario is a four-channel system because it can micromanage brake action in a skid to where only the affected wheel or wheels is pulsed. A three-channel system has two sensors in front and one in the rear. The rear sensor is located in the axle housing and affects both rear brakes. The one-channel system is rear antilock only with a single sensor in the rear axle housing. We normally see one-channel on trucks with rear antilock brakes.

The proper way to use antilock brakes is to never pump the brake pedal in a panic stop. Instead, apply a solid, steady pedal and let the antilock braking system to do what it was designed to do.

If you have a malfunction in the ABS, first physically check all wiring and the brake sensors. Check the brake sensors for metal shaving and other debris, which could cause false feedback to the electronic ABS controller. False feedback causes the ABS to trigger when it shoulder or not function when it should.

You're probably not going to have an ABS scan tool at home, however, any reputable repair shop will have one if you can't find a physical reason for your ABS's malfunction. With a fault code, you can then proceed with your ABS troubleshooting. Whatever the malfunction, the fix is easy once you establish the fault.