An engine needs fuel to run. Since fuel is flammable and generally explosive, it is kept in a tank a safe distance away from the explosions going on inside the engine. This presents the problem of how to get the fuel from the tank to the carburetor or fuel injection system that feeds the engine the fuel. Employing gravity would be the simplest, but driving around with 30 gallons of fuel above the vehicle would not do much for handling, or safety. Enter the fuel pump.

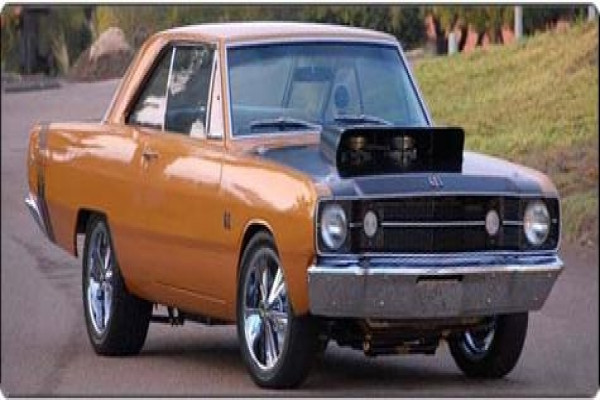

Show Starter.

The fuel pump's sole purpose is to take fuel from the fuel tank and deliver it according to the demand of the engine. In earlier carbureted vehicles, the fuel pump was usually an engine driven mechanical device affixed to the engine itself. There was usually enough fuel left over in the carburetor fuel bowls to get the whole show moving again when the ignition key was turned. Carburetors are now about as common as console black and white TV sets, and fuel injection is the new fuel delivery standard.

Fuel injection systems require a higher working pressure, so the modern fuel pump is capable of maintaining the pressure and flow required by a fuel injection system. To accomplish this task the modern fuel pump runs via electricity created by the alternator. It almost goes without saying that without a properly operating fuel pump the show is over before it starts.

Pump In, Pump Out.

Since the fuel pump is electric-essentially an electric motor-it can be located away from the engine. The motor turns rollers or turbine vanes inside the fuel pump. The rollers take fuel from the tank, pressurize it, and deliver it down the fuel lines into the engine. A fuel pressure regulator controls fuel volume, so the fuel pump keeps spinning away regardless of what the engine demand is up to. Having the fuel pump divorced from the engine has spawned all manner of fuel delivery arrangements. There are inline single fuel pumps, single in-tank pumps, and even a combination of in-tank and inline. For these reasons, it is essential that a service manual be consulted before attempting to service a vehicle fuel pump.

The symptoms of a fuel pump that has grown tired of pumping include excessive whining, hard engine starting, or bucking and loss of power under full throttle conditions. Before replacing the pump, first be sure that filters, fuel pickups, fuel pump relays, and electrical connectors are in good working order. A clogged fuel filter, for instance, can restrict flow and cause some of the same symptoms. Finally, exercise the utmost in caution if working with gasoline. Do not work near water or wall heaters as their pilot lights can ignite fumes. Use safety glasses, gloves, approved containers, and have a fire extinguisher nearby.